Final project meeting

At the beginning of January, the project team met for the final meeting in Espoo…

read more

Fraunhofer-Gesellschaft is the largest organization for applied research in Europe and has 76 Institutes at different locations in Germany, each focussing on specific research topics. The Fraunhofer Institute for Silicate Research ISC as part of it is a research institute devoted to chemistry and materials development, mainly targeting the areas environment, resources, adaptive systems, climate, energy and biomedicine.

The Fraunhofer ISC focuses on developing materials with new or enhanced properties for customized applications, and on methods of manufacturing and processing such materials. The institute’s core competencies are acquired through self-financed fundamental research and elaborated with the market requirements in view. These competences include the synthesis of inorganic and hybrid functional materials, ceramics and glass, preferably using chemical nanotechnology techniques. Material processing techniques for the production of suspensions, powders, fibers, coatings, microstructures and composites. Material characterization, analysis and optimization, and procedures for monitoring processes. The Fraunhofer ISC is a materials research institute whose mission is to develop innovative materials for tomorrow’s products. The institute deliberately focuses on the economic and social challenges that will characterize our future: energy, the environment and health. Starting with the manufacture of materials, continuing through processing, and culminating with the finished product, the institute strives to use energy and resources more efficiently throughout the entire value chain. We have opted for an approach in which we constantly improve our manufacturing processes and develop new, multifunctional, tailor-made materials. The benefits of nanotechnology are harnessed in a responsible manner in order to extend the properties and functions of materials. Fraunhofer ISC had a budget of around €34 million in 2019, including €24.7 million in venue funding from contract research. In 2019, the institute had 466 employees.

The Group Chemical Coating Technology develops functional coatings with different functionalities. Based on the own developed material class nearly all subtrates can be equipped with new or enhanced properties, metals, glass, polymers, papers. The spectrum of functions ranges from hydrophobic to easy to clean, anti-scratch, anti-corrosive and many more. The coatings could be modified to be – at least partly – bio-based and/or degradable. The Fraunhofer ISC has all the equipment needed for the synthesis and characterization of coating materials: for quality control of the coating solutions (spectroscopic methods, methods for determining viscosity, refractive index) as well as for cured layers. Fraunhofer ISC has also pilot plants for the production and application of the coatings.

Fraunhofer ISC has the following equipment:

Continuous coating equipment: roll-to-roll pilot coater (500 mm coating width, 600 mm substrate width) in ISO 8 clean room with slot dye, rotary screen printing, curing (sintering up to 600 °C, IR) for continuous application of films on flexible substrates.

The role of Fraunhofer ISC in Wuerzburg within the project is the coordination, administration and management of the whole project. Besides this ISC is also responsible for the coordination of the dissemination and exploitation of results.

On the technical side Fraunhofer ISC will take over the development, modification and characterization of hybrid coating materials (ORMOCER®) and the combination of it with cellulosic materials from the partners.

By adjusting the chemical composition and optimizing the processing mulch paper with increased stability (chemical, environmental and mechanical) e.g. by hydrophobization can be improved while maintaining the biodegradability. Of course, Fraunhofer ISC also performs the correlating characterization in order to evaluate the adjustment of the hybrid coating systems. For the most promising systems Fraunhofer will perform a technology transfer to the project partner SurA Chemicals GmbH.

The task from Fraunhofer ISC are the usability of novel composite or as a coating on previously used mulch papers to stabilize them as a self-supporting stand-alone paper:

To reach the targeted goals, the project partners work hand in hand and to make sure that the results can be transferred into the production process after the end of the project, and an intensive exchange between the partners and countries is achieved. The project work is portioned in various technical activities, which, in addition to the important aspects such as reporting, dissemination and explications represent the center of the project.

At the beginning of January, the project team met for the final meeting in Espoo…

read more

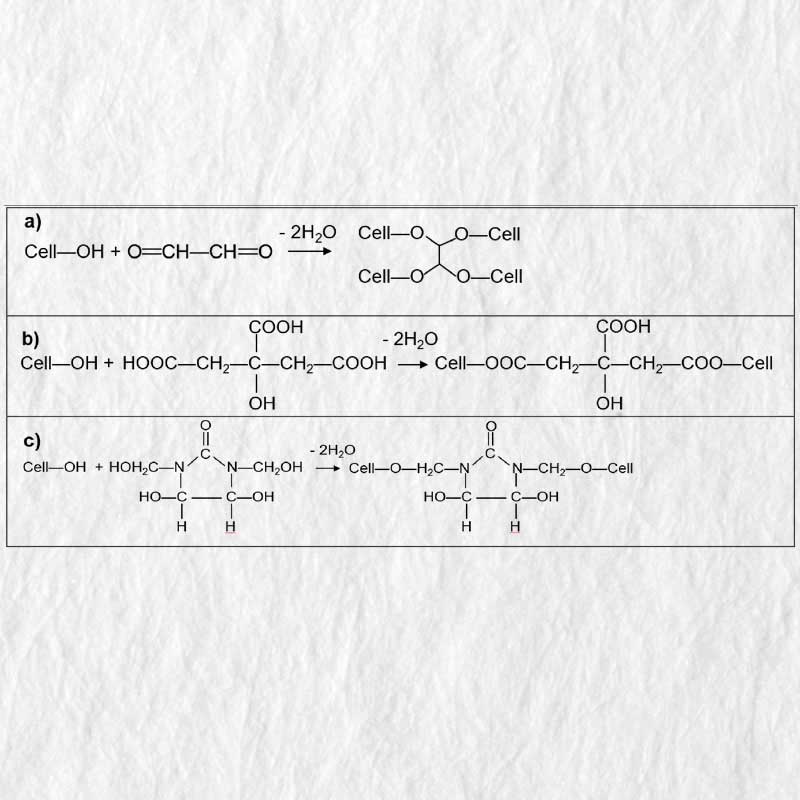

VTT made a comparative study on the Effects of Chemical Crosslinking Agents on NBSK Handsheet.…

read more

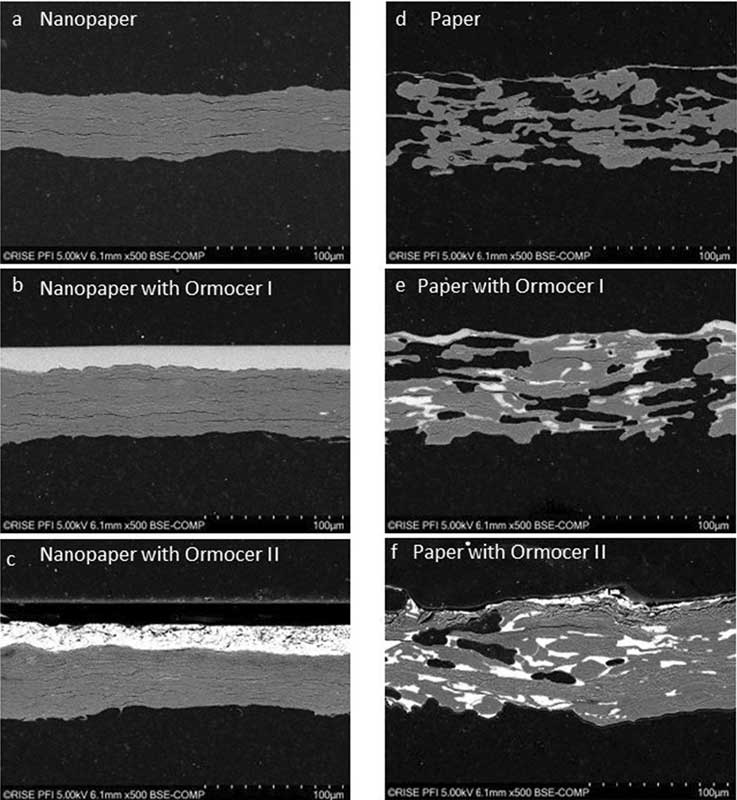

The RISE PFI project team, together with Fraunhofer ISC and VTT, has published an article…

read more